Table Of Content

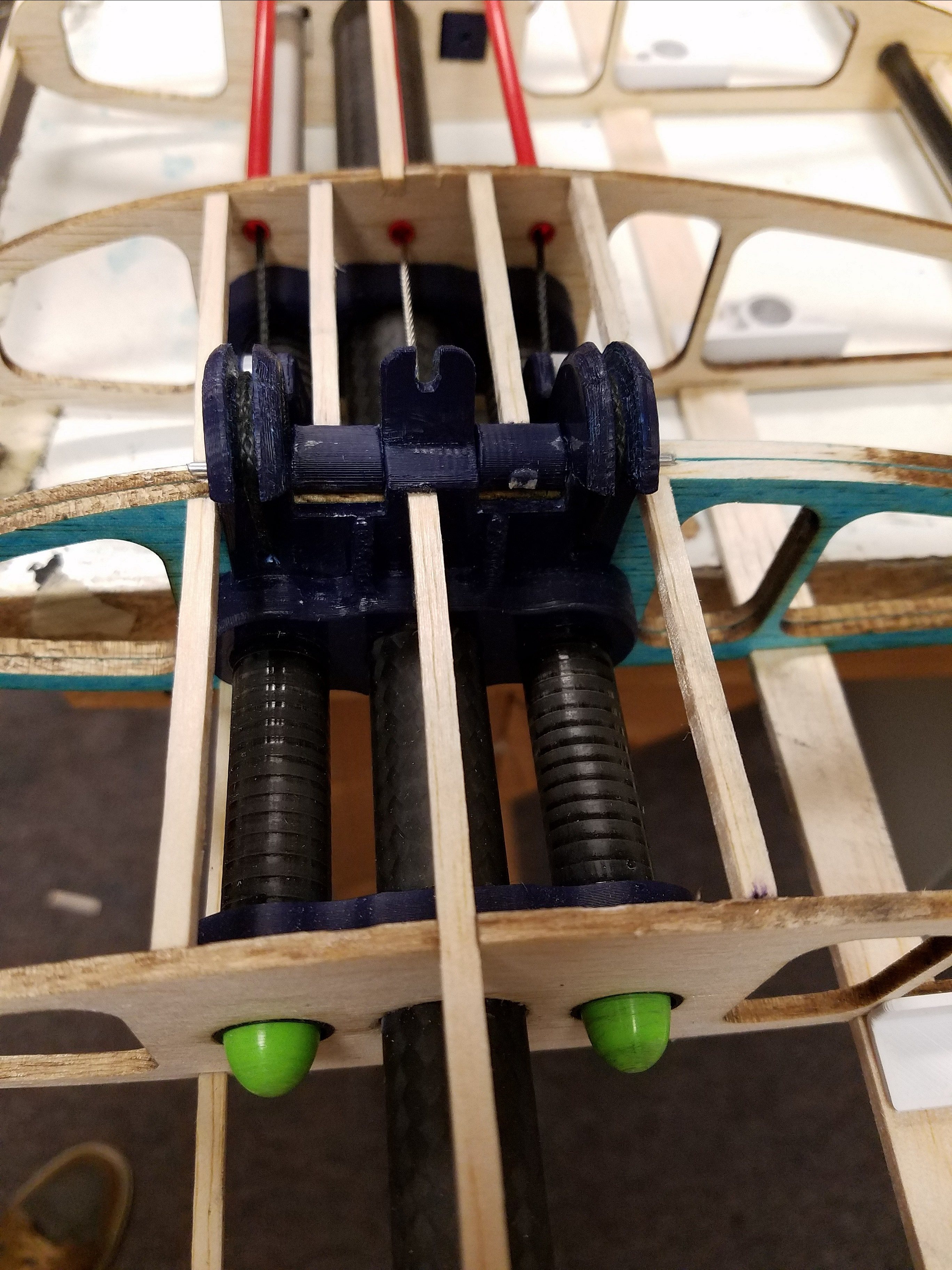

The airplane must be able to conduct a delivery flight, a medical transport flight, and an urban taxi flight. Teams also conducted a ground mission demonstrating how quickly they can change their aircraft configuration from delivery to medical transport to urban air taxi. This year's flight objective was to design, build, and test a remotely operated radio control airplane for Urban Air Mobility. A traditional twin-tractor monoplane aircraft configuration with a conventional tail and custom dual-purposelanding gear was selected. A two-skid landing gear configuration withminimally protruding wheels was developed to address the requirement that the landing gear be identicalfor flight missions and the rough field Taxi Mission. The skids provide optimal maneuverability over thecorrugated roofing panel in the Taxi Mission, and the protruding wheels maintain a low-friction interface for takeoff roll.

making business mobile

Over the course of the year, we design, analyze, prototype, and fly numerous aircraft for a given competition. The aircraft is required to carry vaccine vial packages as its payload and must fly the standard mission profile for each lap. However, the aircraft is required to land anywhere on the runway and taxi to the designated vaccine vial package drop area. The aircraft must repeat the procedure until all vaccine vial packages have been delivered to the designated destination (minimum 1 vaccine vial package is required to be delivered) within a 10 minute flight window. The scoring function for the competition indicates that aircraft top speed, which is impacted by aerodynamic design and correlates with the propulsion system mass fraction, are the primary design drivers.

Exploration Place unveils plans for major overhaul - Wichita Eagle

Exploration Place unveils plans for major overhaul.

Posted: Mon, 05 Jun 2017 07:00:00 GMT [source]

food

Making green even more attractive, many local, state and federal government incentives are offered for installing energy efficient products. The USU Design/Build/Fly team, pictured above, took 22 out of 107 teams, one of their highest scores in recent years. Our team name is ‘Anteater Flight Club,’ since we are working on the ‘Design, Build, Fly’ team and our primary focus is on the aero part of the project directly correlated with the flight aspect. Designed to hold as many syringes as possible within the fuselage, while still flying quickly. Information on due dates for the proposal and design report phases will be posted here once it becomes available.

wraps

A tail dragger landing gear configuration was chosen to minimize drag while simplifying banner loading. Due to the takeoff distance constraints of Missions 1 and 3 and the emphasis on large amount of payload the wing was designed to be high lift while not sacrificing too much performance during cruise. To minimize the wingspan, a dual counter-rotating motor, biplane configuration with a cruciform empennage was chosen. As the aircraft has an unusually short span, the wings are incapable of producing significant roll stability. The aircraft uses two counter-rotating motors resulting in no net torque on the aircraft from the propulsion system.

The Utah State University Design/Build/Fly team returned from its April competition in Wichita, Kansas, in the top 20 percent of all teams. Designed to carry a large number of sensors within the fuselage and extend and retract a tow mid-flight. GREEN SERVICESThanks to a growing market of green construction products, building green no longer means breaking the bank.

NJIT Aero Team Designs, Builds and Flies Their Radio Controlled Plane - NJIT News

NJIT Aero Team Designs, Builds and Flies Their Radio Controlled Plane.

Posted: Fri, 22 Mar 2019 07:00:00 GMT [source]

To minimize the drag in Mission 3, a twin-boom, twin-motor monoplane configuration with an H-tail empennage was chosen. The twin-boom configuration was chosen to separate the two rows of attack stores to reduce drag, and to distribute the load on the wing. The twin motor configuration also allows differential thrust for yaw control, eliminating the need for rudders. The wing is designed to fold along the chord to reduce the span from 6.07 ft to 2.75 ft in the folded configuration. A conventional monoplane configuration with a twin-tractor propulsion system was selected. The shape of the fuselage is designed to carry 8aluminum bars in a single file line to minimize profile drag.

List of top 5 finishes by university

The Manufacturing Aircraft (Mark IV) was designed to fit aroundthe Production Aircraft, resulting in a Manufacturing Aircraft comprised of two sub-assemblies with hollowwings and tails. Instead,stability control is provided by ailererons augmented by a rudder and elevator for both aircraft. To encourage innovation and maintain a fresh design challenge for each new year’s participants, the design requirements and performance objective will be updated for each new contest year. The changes will provide new design requirements and opportunities, while allowing for application of technology developed by the teams from prior years.

The aircraft must complete three laps as fast as it can within a 5 minute flight window for this mission. However, the aircraft must carry the payload, which are syringes and a minimum of ten syringes is required. Designed to carry a payload that is 30% of its body weight and fly with a several foot PVC pipe attached to one wingtip, while being able to be assembled in five-minutes from a suitcase. Maximizing strength while minimizing weight were the main driving factors of the design, and the composite molded wings and fuselage reflect this design decision. In order to maximize thrust to enable a large banner a dual motor configuration was chosen.

THE TEAM

He is an avid world travel who regularly studies and practices authentic design and architectural principals. The firm works with the best and most well regarded artisans, manufactures, vendors and architects in the world, including AD 100 ‘s Rios Hale Clementi Studios. We love DIY aircraft because it is an inexpensive way to get started and you can always reuse the electronics from the aircraft on another kit or project.

For more information, visit , or follow AIAA on Twitter, Facebook, LinkedIn, or Instagram. Starting with a computer simulator is probably less exciting but it is absolutely the most efficient use of your dollars and time. Flying on a simulator is the fastest way to build up the critical muscle memory needed to fly actual aircraft. Involvement goes back years, as the DBF student section took first place in 1999 and 2000. We are comprised of teams of passionate students at Georgia Tech from all majors, backgrounds, and grade levels. The team aims to construct two prototype aircrafts and one final competition aircraft.

Located in Los Angeles, California, our fabrication facility is a one-stop shop to design, build, wrap, and repair your mobile business. Financing keeps more cash in your pocket now while you’re getting your new mobile business up and running. Lease a food trailer or get a food truck loan through one of our trusted financing partners. For over a decade SoCal Contractor has been one of the best luxury home builders in Southern California. The company has a Houzz ranking of #1 for four years in a row for the Southern California region. The President of the firm, Roy Yerushalmi, is a second-generation builder and a graduate of the Construction Management Program at the University of Houston.

Every year there are a new set of rules published by the AIAA for the DBF competition. The 2022 competition mission is to design, build, and test a vaccine delivery aircraft that meets each of the 3 mission profiles. The competition will take place in person on the 21st-24th of April 2022 in Wichita, Kansas. This year marks the largest-ever flyoff participation, with more than 1,000 students on 93 university teams attending onsite. Teams from 12 countries, including 32 US states participated in the full DBF Competition, including submitting design reports and attending the flyoff.

Our mission is to help businesses of all sizes bring their passion to customers and communities through eye-catching, self-contained, and mobile point-of-sale equipment. Get a fully loaded concession trailer including all cooking, refrigeration, storage and safety equipment for only $58,000! The “Workhorse” food trailer is perfect for starting a taco trailer or other mobile food business on a budget. About AIAAThe American Institute of Aeronautics and Astronautics (AIAA) is the world’s largest aerospace technical society. With nearly 30,000 individual members from 91 countries, and 100 corporate members, AIAA brings together industry, academia, and government to advance engineering and science in aviation, space, and defense.

Furthermore, a linear cam separates different ranges of servo travel into different control outputs,allowing a single servo to actuate the rudder, elevator, and ball drop mechanism. A containment cagemounted atop the aircraft fuselage carries up to six balls, with three sides of the cage exposed to thefreestream as required. The objective for this year's competition is to design, build, and test an aircraft that can carry a payload weighing over 30% of its body weight, while also being able to fit into a suitcase in its disassembled form. At Firefly, every food truck or food trailer we build is the best one we’ve ever made. Firefly manufactures the world’s best custom food trucks, concession trailers, and experiential marketing vehicles.

To provide roll control, the vertical control surface is bisected and controlled independently to create rudderons. Since the center of mass is at a high elevation compared to the width of the landing gear, the aircraft uses a quadricycle configuration to maintain stability during takeoff and landing. A mathematical formula outlined in the rules calculates each entry's score, which lately combines design report and performance scores from fly-off missions. So it was natural for its hometown science center, Exploration Place, to choose aircraft design, engineering and manufacturing as the theme for its new signature STEM exhibit gallery. Teams were tasked with designing an aircraft for back country operations such as medical transport, cargo delivery, and rough runway operations. The UW’s “Dawg Sled” was manufactured using novel techniques such as 3D printing and composite structures.

Hollow-molded composite construction techniques for the aerodynamic surfaces andfuselage maximized the structural efficiency of the aircraft and minimized aircraft weight. After a year’s hiatus, the UW DBF team participated in their second AIAA Design Build Fly Competition. The aircraft was designed to carry an range of volume- and/or weight-intensive payloads. Despite this only being the second year of entry, the team was one of only seven teams to complete both flight missions. Design for the year focused on the creation of a UAV capable of deploying, towing, and retrieving an internally-stowed mock sensor, and capable of ferrying a high number of these sensors.

No comments:

Post a Comment